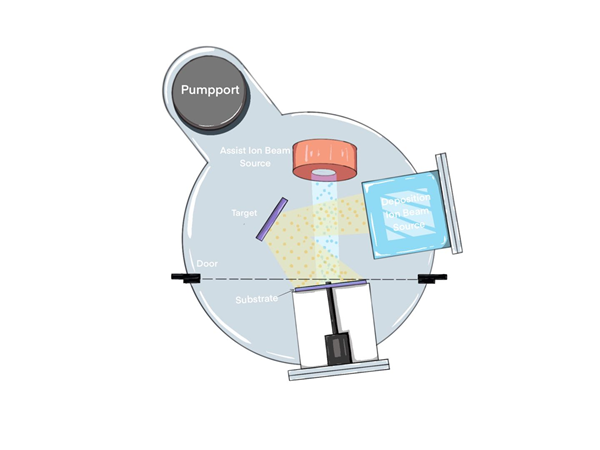

The ions emitted by the ion source are extracted, accelerated and focused to form a beam. The target placed in the high vacuum chamber is bombarded with the ion beam, and the sputtered atoms are coated. Oxygen is introduced into the cavity and reacts with the metal gas to realize the oxide film. Due to the high-energy process introduced by ion beam sputtering deposition, a film layer with good consistency, high density, amorphous structure and excellent firmness is formed, which brings excellent environmental stability and mechanical durability. The film produced by IBS has good roughness and small scattering loss.

Compared with other types of deposition methods, due to the characteristics of slow deposition rate and high control accuracy, it is often used to generate products with high-precision spectral requirements, such as GFF.

However, the disadvantage of IBS is that it has some limitations on evaporation materials and can only be used to process metal oxides; And the processing cost is high.