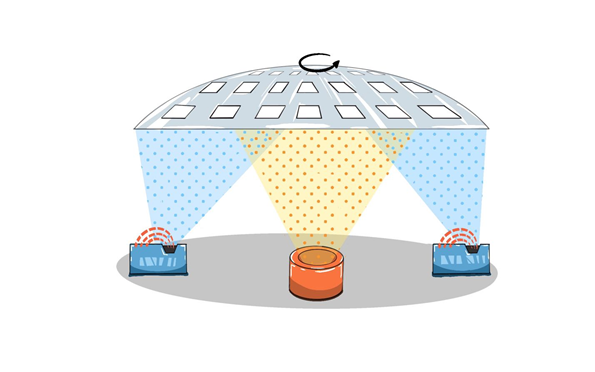

Under the vacuum condition, the gas is ionized by gas discharge, and the evaporated substance or its reactant is evaporated on the substrate while the gas ion bombards. Ion assisted deposition is actually based on electron beam evaporation, introducing ion bombardment to increase the kinetic energy of the evaporated film. Compared with electron beam and thermal evaporation, the film has higher density. In addition, the gas ion beam can be used to clean and etch the substrate surface, thereby enhancing the firmness of the film layer.

By introducing ion assistance, the film has higher firmness, better mechanical properties, better environmental reliability and lower film scattering.

However, ion assisted deposition is not applicable to all materials, for example, MgF2 may be decomposed during deposition.

Compared with EB process, cost, spectral stability and reliability are comprehensively considered.

Compared with IBS process, it has higher scattering and absorption loss.